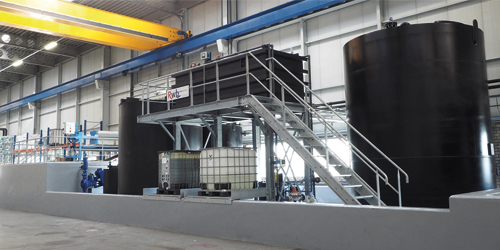

Chemical plant and DND plant – detoxification, neutralization and dewatering

About Van Merksteijn

Van Merksteijn International is one of the largest producers of reinforced products and sustainable fence panels in the world. Van Merksteijn International has production locations and storage units all over Europe. All production processes take place under our own management, which means that consistent quality can be guaranteed.

Where its influence permits, Van Merksteijn International is committed to combating climate change and its consequences. Van Merksteijn International’s environmental performance is continuously improved, resulting in the lowest possible energy and fuel consumption and the lowest possible environmental pollution.

Our project

For the production of galvanized steel wire, Van Merksteijn has realised two hot-dip galvanizing lines with corresponding refueling pits (2) for the storage of hazardous substances.

These changes are necessary in order to increase the production capacity from 880.000 tons per year to 1.040.000 tons per year.

In this process chemicals are used and waste water is produced. A distribution and treatment solution must be designed for the whole process.

Process chemicals and purification of the produced waste water

Waste water from the galvanizing process is approximately 144 m3 per day

Chemicals are used in the process for which RWB has built a chemical plant. This installation consists of a filling, storage and transport system for hydrochloric acid and a storage and disposal system for used chemicals.

RWB also supplied a facility to treat the waste water released from this galvanizing line. The waste flows from the galvanizing line are treated in an DND installation (detoxification, neutralization and dewatering) in such a way that the residual flow may be discharged into the sewerage system. In the DND plant, the concentrated inorganic compounds (in this case metal solutions) resulting from the galvanizing process are treated batch by batch.

Toxic and carcinogenic ions are converted into another, less toxic ion form at a low pH (acidity). The low pH required for this purpose is achieved by the addition of an acid. During neutralization, a higher pH is achieved by adding an alkaline solution.

Flocculants and coagulants are then added in order to obtain an easily filterable precipitate of metal hydroxides. The formed metal hydroxides are separated and removed by, for example, dewatering or by sedimentation in a settling tank.

What is realized?

Our customer speaks

“With both of RWB’s solutions, Van Merksteijn International uses a system that identifies various waste streams within its own organization and ensures that they are processed correctly.”

Van Merksteijn International

“Strive towards sustainability through the implementation of an Environmental Aspect Register”

A water treatment plant to minimize any environmental impact.

Van Merksteijn continuously evaluates its environmental impact by means of an Environmental Aspects Register. Van Merksteijn International’s environmental performance is continuously improved, resulting in the lowest possible energy and fuel consumption and the lowest possible environmental pollution.

Also make your waste water treatment more sustainable?

More information about our activities within the communal wastewater sector? Feel free to contact us via the number below or use the contact form.