The membrane technology for removal of suspended and colloidal particles from water is microfiltration (MF) or ultrafiltration (UF).

Suspended substances, turbidity and micro-organisms can be removed outstandingly with the help of micro- or ultrafiltration. Both techniques are therefore frequently used as pre-treatment technologies for reverse osmosis and present an alternative to more traditional water treatment techniques such as sand filtration.

The difference between microfiltration and ultrafiltration is in the membrane pore size. Microfiltration pores are on the order 0.1 – 10 µm in size and are able to completely hold back bacteria and partially hold back viruses. Ultrafiltration pores are on the order of 0.005 – 0.1 µm in size and can also completely remove viruses from the water.

The most important advantages to micro- and ultrafiltration are:

Operation Micro and ultra-filtration membrane filtration

Microfiltration and ultrafiltration are physical separation methods that work according to the sieve effect. The separation is realized on the basis of particle size. Particles larger than the membrane pores are held back by the membrane. The driving force for micro- and ultrafiltration is a pressure difference across the membrane from supply to filtrate side.

Both types of membranes can be operated dead-end or cross-flow. In the dead-end operation, all the water is pressed through the membrane. In the cross-flow operation, the supplied raw water is circulated along the membrane surface. This creates speed and turbulence, so that more polluted water streams can be treated.

The membrane surface has to be periodically cleaned. The cleaning can be realized in multiple ways. The most familiar is back-rinsing of the membrane with filtrate. Air purging is also possible along the raw-water side of the membrane. Further, a chemical cleaning can be applied.

Experience RWB

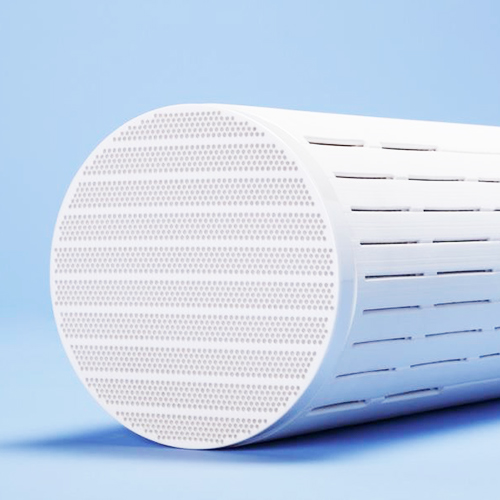

RWB has knowledge and experience with design and realization of micro- and ultrafiltration installations. For microfiltration applications, RWB prefers to apply ceramic membranes as a robust and sustainable alternative to polymer membranes.

The ceramic membranes are applied in the METAWATER compact and modular systems. The membranes have a unique membrane surface of 25 m2 per membrane and pore size of 0.1 µm.

For ultrafiltration installations on the basis of polymer membranes, RWB has a standardized Culligan® line.

The conducting of pilot tests is one of the options that RWB has to come up with an optimal process design.

More information about Micro and ultra-filtration?

Feel free to contact us via the number below or use the contact form.