Upgrading valuable raw materials and waste water reuse

About Inashco

Inashco was founded in the Netherlands in 2008 to offer a unique patented technology, developed by the Technical University of Delft, for the recovery and upgrading of fine non-ferrous metals from municipal waste ash (bottom ash).

Delft University of Technology has extensive experience in researching the ash properties of waste incineration plants and developing optimal recycling technologies. After extensive exploration in the field of wet processing techniques, TU Delft unveiled a ground-breaking dry recycling technology that is simple, robust and effective.

Our project

For decades, bottom ash has been used as a secondary building material in civil engineering. Bottom ash is used as a foundation under roads, for example. There are now more than 20 billion kilos of bottom ash under Dutch roads. In order to be able to use this raw material, certain rules have been drawn up to prevent harmful substances from spreading.

The waste processing industry complies with these regulations, but is working on making the sector more sustainable and the bottom ash cleaner. It looks at the possibility of removing the IBC category (building materials that may only be used with insulation, management and control measures). To achieve this, it is necessary to improve the quality in such a way to create a raw material that can be used without insulation measures.

Washing bottom ash to improve quality

The effluent released contains leachate, a complex and difficult to treat material.

A proven method to improve the quality of bottom ash is to wash the ash. The application of this technique falls under the Green Deal concluded with the government. Within this deal, it was also agreed that the recovery percentage of non-ferrous metals should be increased.

During washing, some of the contaminants (metals and salts) are removed from the bottom ash by means of water, with or without additives. The washing step can be entered in the process itself (integrated washing process).

Soil ash is washed on the ENCI site in Maastricht. The water used for this purpose must be purified, removing the sand/sludge and allowing it to be reused in the process.

What is realized?

Our customer speaks

“RWB designed an installation to process the waste water and to convert it into process water. This makes the installation not only economically profitable, but also sustainable and this suits the current trend of closed cycles and the recycling of raw materials.”

Inashco

“Sustainable urban mining; raw materials from household waste”

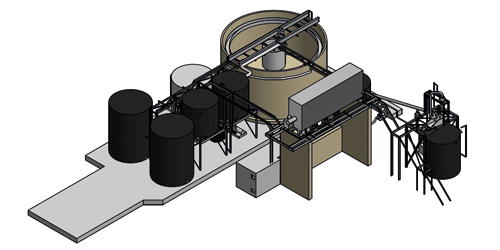

A water purification system to process complex waste streams and to minimize environmental impact.

Inashco and Delft University of Technology are working together to refine the technology to maximize efficiency. Today, Inashco has more than 20 bottom ash processing plants that process and generate energy for more than 4 million tons of waste worldwide.

Also make your waste water treatment more sustainable?

More information about our activities within the communal wastewater sector? Feel free to contact us via the number below or use the contact form.