The membrane bioreactor is a technology that results in a compact set-up with high removal of organic components and inorganic nutrients from wastewater.

The combination of a biological purification process with physical separation by means of membrane technology has the following advantages:

Operation ceramic membrane filtration

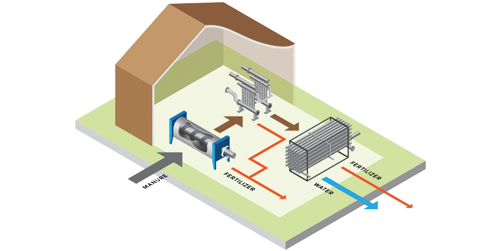

In the bioreactor, organic components and inorganic nutrients present in the wastewater are converted by bacterially active sludge. The bacteria use these wastewater substances as food for their metabolism and multiplication process. When an aerobic bacterial culture is used, oxygen is also needed, and the reactor is aerated.

The conventional sedimentation step for separation of sludge and purified wastewater is replaced in the membrane bioreactor by a membrane separation process. Undissolved substances larger than the pore size of the membrane are held back by the membrane.

The big advantage of this separation technique is that the sedimentation properties of the sludge no longer play any role. Because the bioreactor can therefore be operated with a higher MLSS level, a smaller volume suffices.

The membrane separation step of the membrane bioreactor can be set up sidestream or be immersed. For the sidestream set-up, the membranes are placed outside the bioreactor and the MLSS is circulated over the membranes. In the immersed set-up, the membranes are immersed in the MLSS, either directly in the bioreactor or in a separate membrane tank..

Experience RWB

RWB has designed and realized various membrane bioreactors. Next to the standard membrane bioreactors in which polymer membranes are used, RWB also delivers membrane bioreactors with ceramic membranes. The ceramic MBR concept has been developed by RWB and thoroughly tested. Application of ceramic MBR provides the following advantages:

Our ceramic membrane technology is very compact and is exceptionally suited for construction in a 20 ft. or 40 ft. container.

RWB has multiple pilot installations with which both polymer and ceramic membranes can be tested. This way, the optimal and most cost-favourable solution can be determined per application.

Realized projects

More information about membrane bioreactors?

Feel free to contact us via the number below or use the contact form.