A complete solution to treat the surplus in manure and digestate.

About Dankers Bio Energy

Dankers Bio Energy operates a digestion plant in which biogas is recovered from a mixture of manure and organic waste products. The biogas is eventually converted into electricity by a heat exchanger. The plant converts 35,000 tons of manure and by-products into electricity with a capacity of 2.544 MW and a production of 10.176.00 MWh per year in four silos. Dankers Bio Energy works closely with operators, farmers and suppliers of co-products in order to achieve a maximum return and to minimize waste flows.

Our project

A surplus of manure on (agricultural) land leads to contaminated soil. In order to prevent this from happening, the European Union has introduced a phosphate ceiling and regulations concerning compulsory manure and digestate treatment. In 2010, Dankers Bio Energy and RWB Water joined forces to jointly develop an innovative solution for the residual products from the biomass recovery unit. The residues are treated and form a single product in which the minerals N-P-K are concentrated.

Efficient use of raw materials

Robust, reliable and proven technique to generate bio-energy, fertilizers and water.

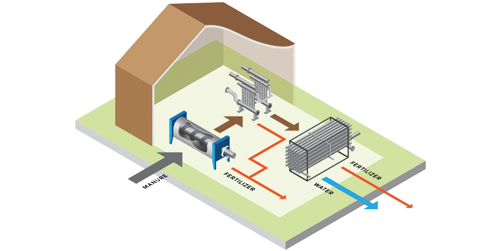

In order to comply with the treatment obligation and to make optimal use of the value of manure, RWB designed a complete solution to treat manure and digestate. As a first step, a separation takes place by means of a screw press so that a thick and thin fraction is created. RWB specializes in the treatment of the thin fraction and pre-treats it by a ceramic membrane filtration step. This leads to a more efficient reverse osmosis process as the last purification step in the chain. The use of ceramic membranes ensures a maximum volume in discharging water. In order to extract all valuable fertilizers from the ceramic membrane filtrate, a reverse osmosis installation is used. This last stage of purification produces dissolvable water and a high concentration of minerals (N and K). An ammonia stripper is used to separate nitrogen from the mineral concentrate. This results in a nitrogen-rich fertilizer (ammonium sulphate >30%). A vacuum evaporator is used as the last process step to produce a concentration of valuable fertilizer in the form of potash (k2O >12%).

What is realized?

Our customer speaks

“The RWB digestate treatment plant has already proven its worth for 7 years. RWB carried out the design as well as the execution and commissioning. In addition, the key components of the installation come from RWB’s own delivery package, which means that we can always rely on RWB for any maintenance questions.”

Dankers Bio Energy

“A proven installation that has been converting waste into valuable products for more than 7 years.”

Reduce digestate volume and the recovery of valuable organic minerals in concentrated form.

The by-products of this plant consist of an RO (reverse osmosis) concentrate and a solid fraction. The RO concentrate is a liquid stream with approximately 7% dry matter, which has passed the membrane. The solid (stackable) fraction did not pass the membrane, it has approximately 25% dry matter. It contains the organic substances that are difficult to digest and the ash residues.

Curious about the possibilities for reuse?

More information about our activities in the reuse and raw materials sector? Feel free to contact us via the number below or use the contact form.